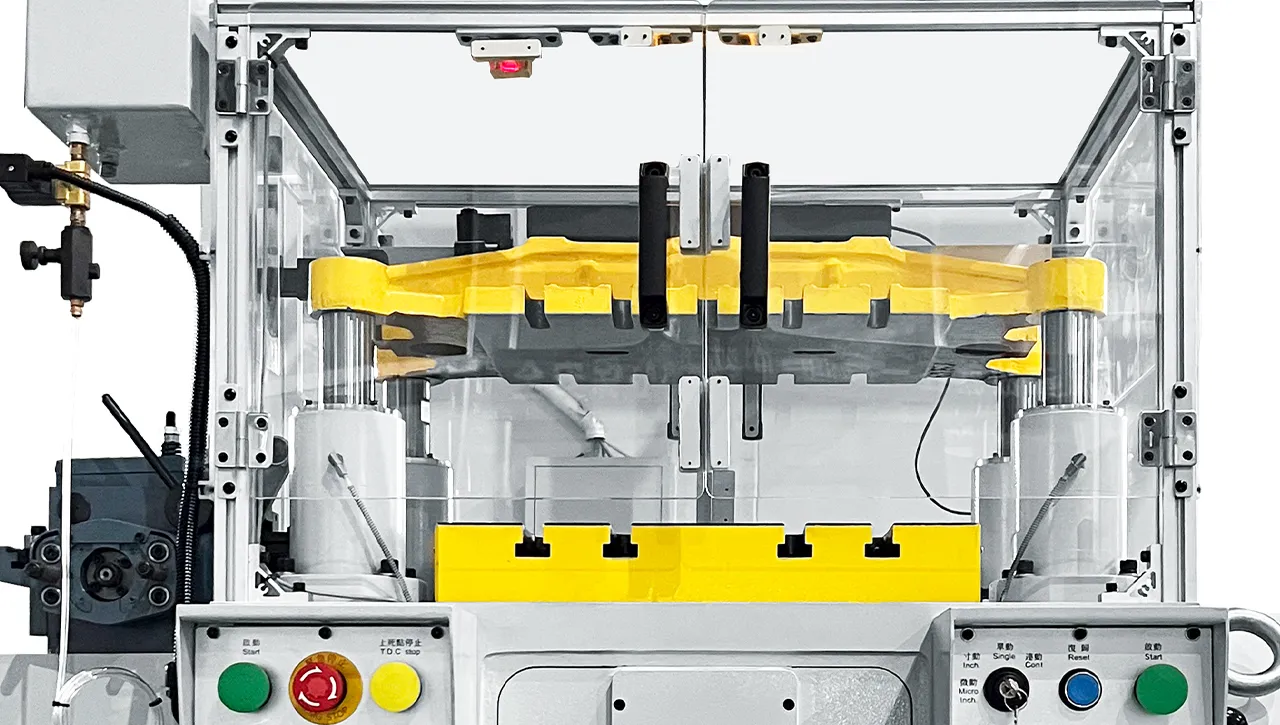

The pull-down design features a closed four-guide post structure and a long table, providing strong resistance to off-center loading, with a completely oil-free slide table surface.

The dynamic balancing system ensures stability and high precision during high-speed operation.

The one-piece cast machine body lowers the equipment’s center of gravity, reducing vibration and noise, providing high stability, extending mold life, and improving the production environment.

The centralized lubrication system reduces piping and prevents component damage caused by aging or ruptured oil lines.

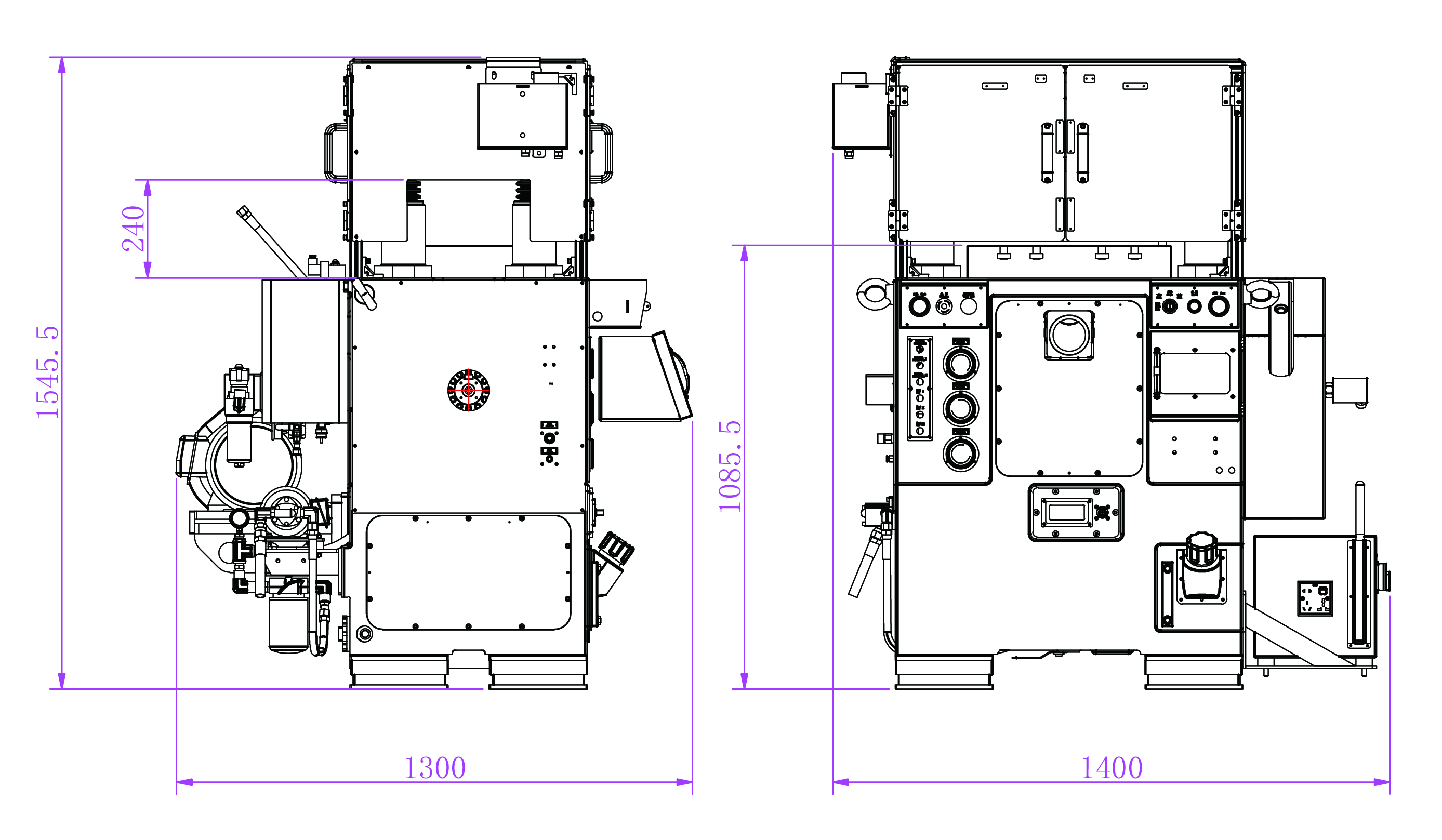

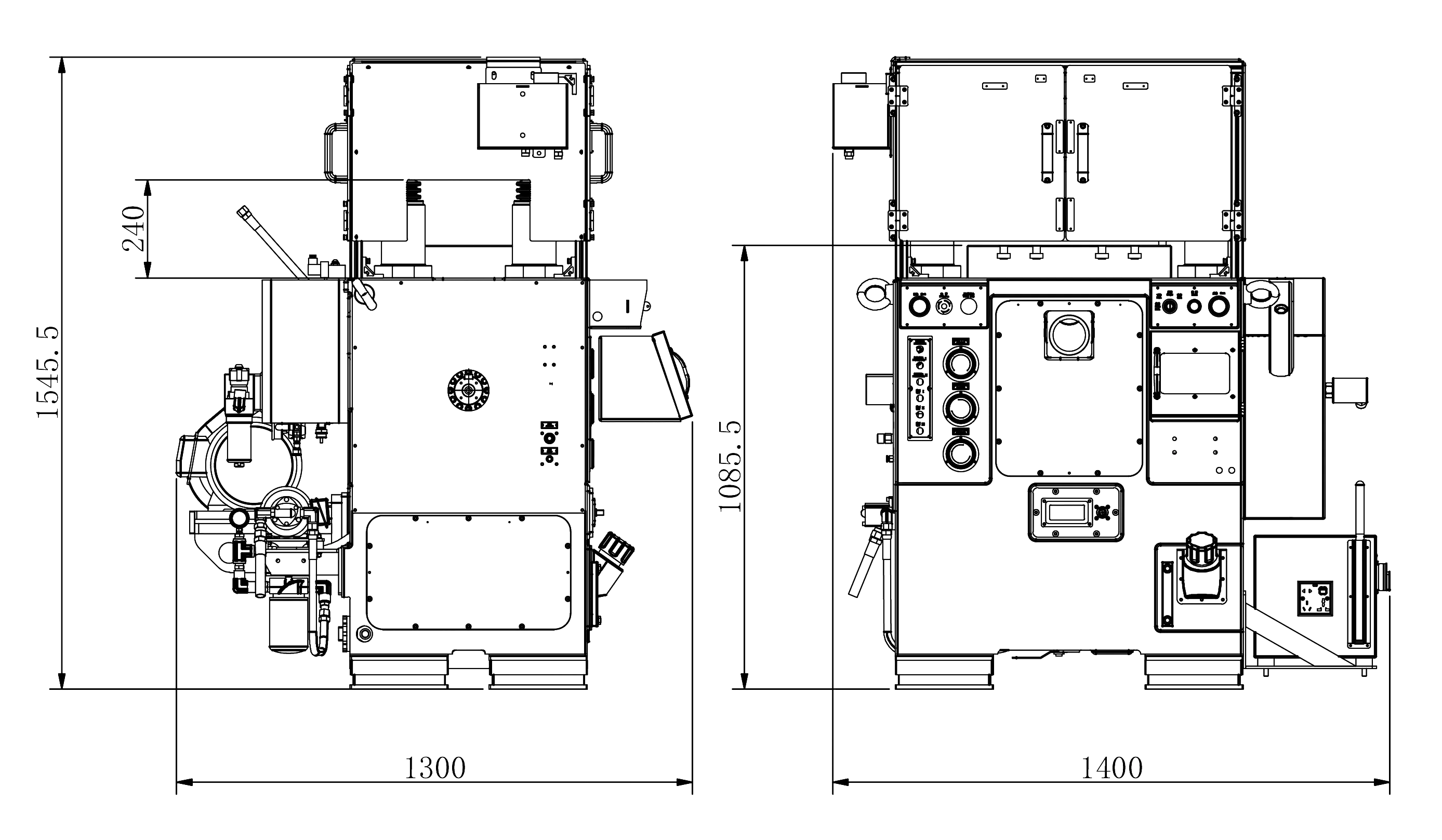

| SMART SERIES UNDER DRIVE PRECISION HIGH-SPEED PRESS | |||||

|---|---|---|---|---|---|

| Model | SMART-25 | ||||

| Capacity | Ton | 25 | |||

| Stroke | mm | 20 | 25 | 30 | 35 |

| Speed | S.P.M | 120-300 | 120-300 | 120-300 | 120-300 |

| Die-Height | mm | 185-215 | 182-212 | 180-210 | 178-208 |

| Bolster Area | mm | 500*400*80 | |||

| Slide Area | mm | 480*350 | |||

| Slide Adjustment | mm | 30 | |||

| Bed Opening | mm | 400*100 | |||

| Main Motor | HP/kW | 5.5*100 | |||

| Lubrication | Automatic Lubrication | ||||

| Speed Control | Inverter | ||||

| Clutch & Brake | Pneumatic dry-running unit | ||||

| Auto Top Stop | T.D.C | ||||

| Shock Absorber | Rubber pad | ||||

WHERE RELENTLESS INNOVATION

MEETS UNCOMPROMISING PRECISION

TAIWAN

PRECISION PRESS