Q01 What are the differences between Crank Press and Toggle Press?

| Crank Press | Item | Toggle Press |

| Crank Connecting Rod Mechanism | Drive Mechanism | Toggle Linkage Mechanism |

| Standard sine wave Short dwell at BDC | Slide Motion Curve | Slower motion near BDC Prolonged pressure holding at BDC |

| Higher speed Simpler structure, easy to maintain Wide applicability Lower cost | Advantages | High BDC accuracy Extended die life Lower noise and vibration |

| Lower BDC pressure Limited accuracy | Limitations | Complex structure, higher cost Low mold compatibility Low SPM |

| General metal stamping, flexible production | Applications | Precision forming, deep drawing, small metal parts |

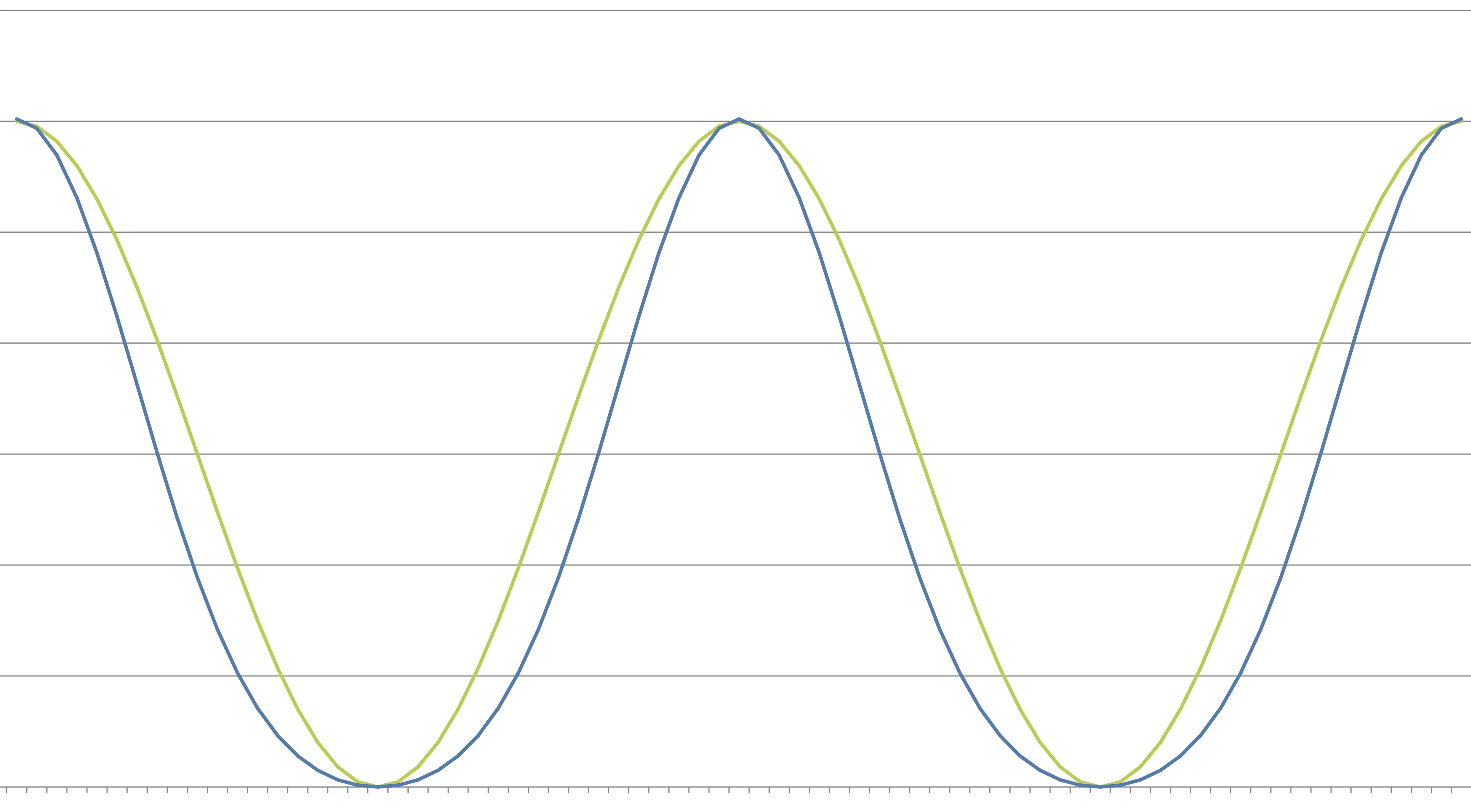

Motion Curve:

| Crank stroke | V/S | Toggle stroke | ||

X-axis: Angle | ||||

| Y-axis: Slide Position | — | Crank stroke | — | Toggle stroke |

Q02: Where are the manufacturing centers?

We have 2 plants in Dongguan, Guangdong.

Q03: How does the Dynamic Balancer work?

Presses are often subject to dynamic imbalance during operation due to various internal and external factors.

Dynamic balancer can control and adjust the press’s motion status during operational process, effectively reducing vibration and ensuring stable high-speed operation.

Q04 Why Vibratory Stress Relief (VSR) is essential?

Main structures of our presses undergo VSR treatment after rough machining.

By applying nondestructive sub-harmonic vibrations, VSR process relieves internal stress, stabilizes the metal and realizes press long-term precision.

Q05: Why is annealing treatment applied to the press bed?

The main structure of MINGXU presses undergoes annealing treatment before machining.

Annealing is a heat treatment process in which the material is exposed to high temperatures for an extended period and then cooled slowly. Its primary purpose is to relieve internal stresses, enhance ductility and toughness, and develop a specialized microstructure.

Q06: What is the value of applying finite element analysis (FEA)?

Finite Element Analysis (FEA) is a technique that uses mathematical approximation methods to simulate real physical systems.

By applying FEA, press structures can be designed with reduced slide deformation and improved rigidity.

Q07: What are the supply sources for the core components (crankshaft and bearings)?

The crankshaft is supplied by Yuexin Crankshaft Co., part of Guangzhou Industrial Control Group (a Fortune Global 500 company).

Bearings are sourced from well-known brands such as NSK and KOYO from Japan, and FAG from Germany.

Q8: What are the characteristics of the press bed material?

The main structure of the press is made of ductile cast iron FCD500.

FCD500 offers higher strength than gray cast iron and has properties similar to steel, featuring high strength, excellent toughness, impact resistance, and fatigue resistance—ideal for high-speed press operation.

It also provides good castability and machinability, allowing for complex casting and easy processing.

Q09: How can I obtain the product specifications?

Contact our technical

sales: Nick Wu (nickwu@mx-press.com).

Q10: How to choose the model and tonnage of a press?

When selecting the tonnage and model of a press, factors such as the type of parts, material thickness, and die specifications should be considered.For more details, please contact our technical

sales: Nick Wu (nickwu@mx-press.com).

Q11: What are the application areas of the products?

Widely applied in the metal stamping industry, including 3C electronic connectors, motor stators and rotors, silicon steel stamping, chains, household appliances, automotive components, lead frames, precision hardware stamping, and other industrial applications.

Q12: What is the precision standard for the press?

According to the Japanese JIS B 6402:2020 standard, MINGXU presses are classified as top-grade precision, exceeding the first-grade accuracy of the national standard GB/T 10923.

Q13: What certifications has MINGXU Press obtained?

Q14: What is the production lead time for the press?

Standard models with a capacity of 80 tons or less have an estimated delivery time of 1–2 months, while articulated and large machines (over 80 tons) require more than 2 months for delivery.

WHERE RELENTLESS INNOVATION

MEETS UNCOMPROMISING PRECISION

TAIWAN

PRECISION PRESS