The dynamic balancing system ensures stability and high precision during high-speed operation.

The oil temperature cooling system maintains internal oil circulation balance, minimizing bed deformation and enhancing bottom-dead-center stability.

A higher force generation point effectively improves the operational stability of the press.

The high-strength cast iron bed undergoes annealing, followed by precision machining and vibration aging treatment to fully eliminate thermal stress, ensuring long-term accuracy of the press.

The centralized lubrication system reduces piping and prevents component damage caused by aging or ruptured oil lines.

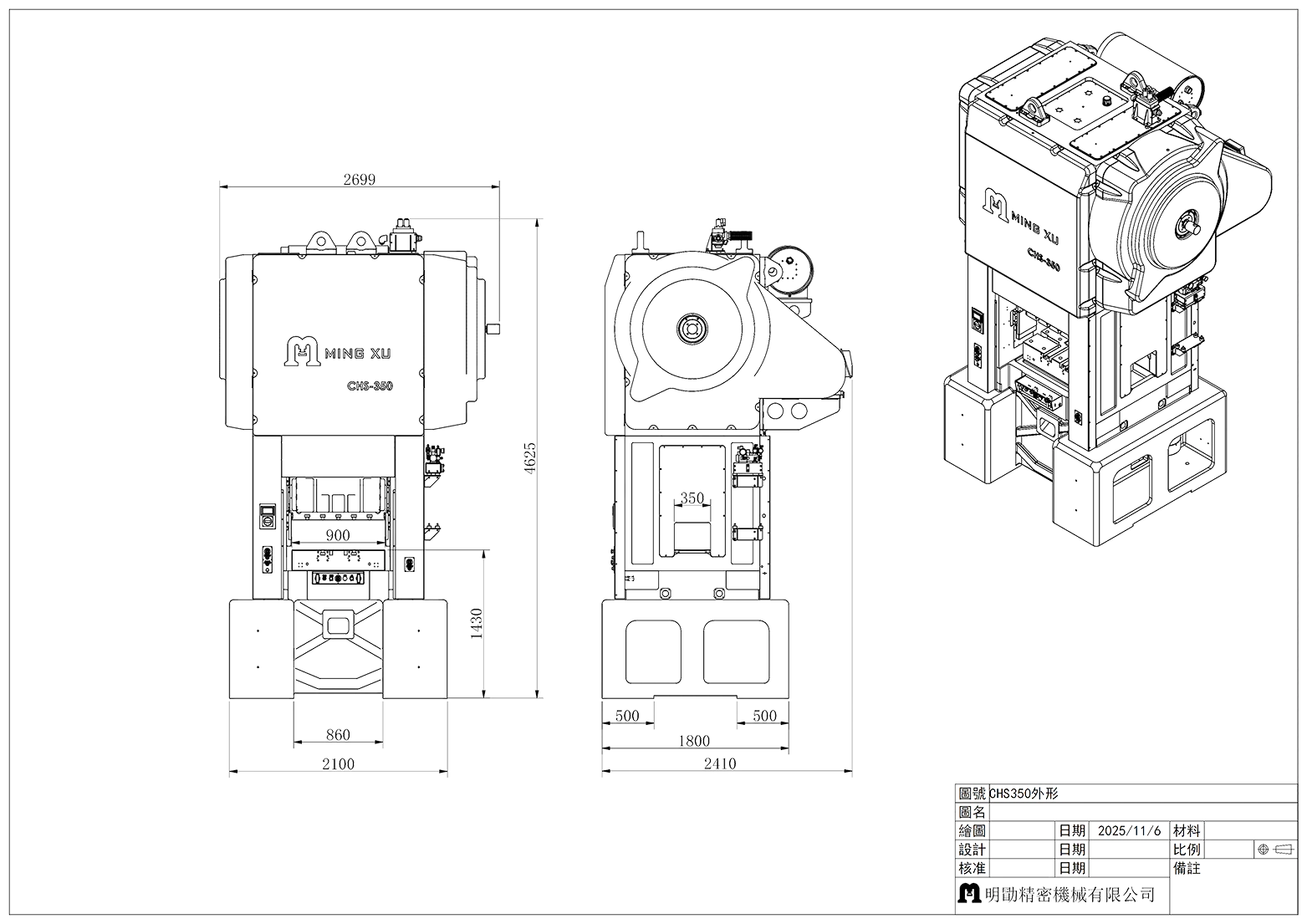

| CHS SERIES - GANTRY SINGLE CRANK PRECISION HIGH-SPEED PRESS | |||||

|---|---|---|---|---|---|

| Model | CHS-350 | ||||

| Capacity | Ton | 350 | |||

| Stroke | mm | 20 | 30 | 40 | 50 |

| Speed | S.P.M | 150-500 | 150-400 | 150-350 | 150-300 |

| Die-Height | mm | 260-310 | 255-305 | 250-300 | 245-295 |

| Bolster Area | mm | 900*750 | |||

| Slide Area | mm | 900*650 | |||

| Slide Adjustment | mm | 50 | |||

| Bed Opening | mm | customized | |||

| Main Motor | HP/kW | 75/55-4P | |||

| Lubrication | Automatic Lubrication | ||||

| Speed Control | Inverter | ||||

| Clutch & Brake | Pneumatic dry-running unit | ||||

| Auto Top Stop | T.D.C | ||||

| Shock Absorber | Damper/Spring Damper | ||||

WHERE RELENTLESS INNOVATION

MEETS UNCOMPROMISING PRECISION

TAIWAN

PRECISION PRESS