The four-guide post structure with titanium-coated steel tubes minimizes dynamic friction, reducing thermal deformation.

The integrated bed design provides high rigidity and stability. After stress relief treatment, it ensures long-term precision of the press.

The gantry-type bed structure is robust and equipped with anti-vibration foot mounts, effectively minimizing deformation during stamping operations.

The dynamic balancing system ensures stability and high precision during high-speed operation.

The oil temperature cooling system maintains internal oil circulation balance, minimizing bed deformation and enhancing bottom-dead-center stability.

The electric die height adjustment system, equipped with a die height indicator and hydraulic slider lock, provides a display accuracy of 0.01mm, ensuring safe press operation while making die setup simple and convenient.

| CHD GANTRY DOUBLE CRANK PRECISION HIGH-SPEED PRESS | |||||

|---|---|---|---|---|---|

| Model | CHD-30 | ||||

| Capacity | Ton | 30 | |||

| Stroke | mm | 20 | 25 | 30 | 40 |

| Speed | S.P.M | 100-1000 | 200-900 | 200-800 | 200-600 |

| Die-Height | mm | 195-235 | 192-232 | 190-230 | 185-225 |

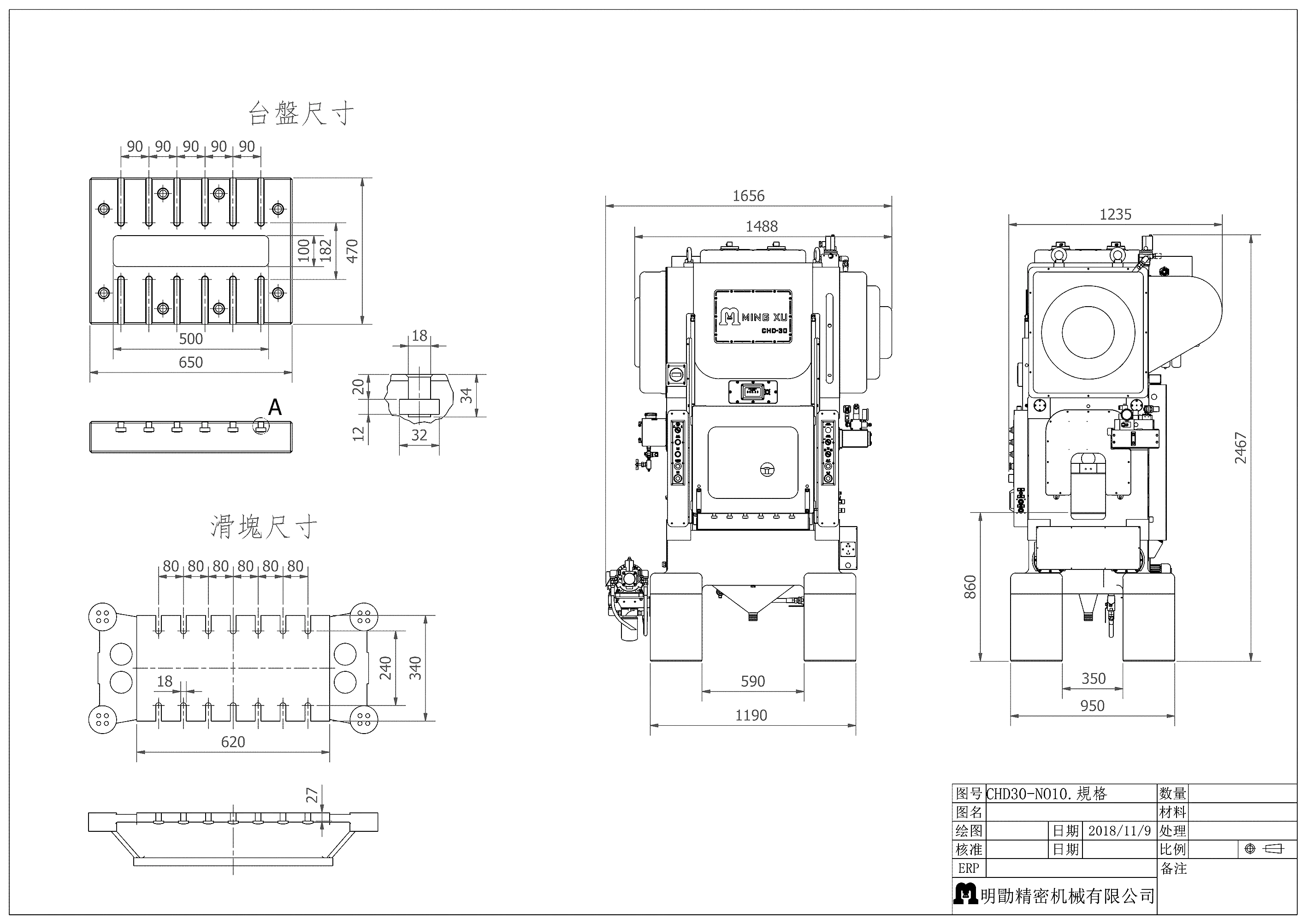

| Bolster Area | mm | 650*470*100 | |||

| Slide Area | mm | 620*340 | |||

| Slide Adjustment | mm | 40 | |||

| Bed Opening | mm | 500*100 | |||

| Main Motor | HP/kW | 10/7.5 | |||

| Lubrication | Automatic Lubrication | ||||

| Speed Control | Inverter | ||||

| Clutch & Brake | Pneumatic dry-running unit | ||||

| Auto Top Stop | T.D.C | ||||

| Shock Absorber | Damper | ||||

WHERE RELENTLESS INNOVATION

MEETS UNCOMPROMISING PRECISION

TAIWAN

PRECISION PRESS